Vintage Audio: Ampex TU-40 Flutter Meter | Telos Alliance

By The Telos Alliance Team on Jul 17, 2015 2:31:21 PM

Vintage Audio: Ampex TU-40 Flutter Meter

Vintage Audio: Ampex TU-40 Flutter Meter

In the digital age of WAV files and hard drives, sound appears as if by magic from a PC or iPhone. But it wasn't that long ago that audio reproduction involved something going around, be it a turntable platter, tape or cassette reel, cart hub, or film reel.

In the ideal world, those rotating parts would behave in a perfectly linear fashion, yielding playback with perfect pitch and timing. In the real world, parts wear, things get wonky, and measuring and maintaining wow and flutter specs was an ongoing challenge. With the quartz control circuits and direct drive transports of later devices, quantum improvements in performance were achieved, although perfection, as always, remained just out of reach. This month's expedition to the attic turned up an Ampex TU-40 flutter meter, just what the doctor ordered to document the anomalies of rotating parts in audio recording/playback devices.

Two measurements are taken to quantify the speed integrity of sound reproducing equipment, flutter and drift. The difference between them is a matter of time and frequency. Drift is a low-frequency long time phenomenon, with frequencies up to 0.2 Hz. Flutter is composed of higher frequencies and shorter times. Frequencies from 0.3 Hz to 200 Hz are indicated on the flutter meter.

Problems with drift may be related to things like tape tension changing as the amount of tape on a reel  changes. Flutter is usually caused by rotating components that are out of round or worn, such as an idler wheel with a flat spot, a bent capstan shaft, or worn ball bearings.

changes. Flutter is usually caused by rotating components that are out of round or worn, such as an idler wheel with a flat spot, a bent capstan shaft, or worn ball bearings.

Wow and flutter degrade the sound of audio in different ways, depending on the frequency where it occurs. From about 5 to 8 Hz, the pitch appears to drift. Above 50 to 200 Hz, the sidebands themselves are heard and perceived as added noise, sometimes called modulation noise. Between 8 and 50 Hz, the tone quality is modified, sounding a bit rougher, although the pitch change itself is not audible. Since the ear's sensitivity to frequency deviation depends on the deviation frequency, the measurements are performed with a weighing filter which approximates the characteristics of the human ear.

There are two standards for measurement of flutter in audio playback devices: NAB and DIN. The NAB standard involves playback of a flutter-free calibration tape recorded at 3 Khz. DIN tests are done by recording and playing back a tone. Although the approach is a bit different, numerous tests have shown that measurements made by either method produce equally valid results.

While the schematic of a flutter meter might look intimidating, the theory of operation is quite simple. A flutter-free tone (typically at 3.15 Khz) recorded at a precise frequency is played back on the device under test. Any variations in playback speed manifest themselves as changes in frequency, or, frequency modulation. So, at the input to the flutter meter, there is essentially a 3.15 Khz center frequency carrier that is being frequency modulated. After being run through AGC and limiter amps to ensure constant level, the signal is run through an FM demodulator. The output of the demodulator is split, one leg going to the drift meter circuits, the other to the flutter meter.

The drift meter amplifier has both a bandwidth and sensitivity switches. Its output drives the drift meter and an output to a front panel BNC connector, typically used for connecting an oscilloscope.

The flutter circuit includes a sensitivity switch and flutter bandwidth filter amp with a range of .3 to 200 Hz.

The flutter circuit includes a sensitivity switch and flutter bandwidth filter amp with a range of .3 to 200 Hz.

The TU-40 also contains an integral wave analyzer which is tunable over a frequency range of 0.5 to 60 kHz in 5 decade ranges. When the wave analyzer is in the circuit, the meter shows only the components of the frequency tuned on the dial. The selectivity of the wave analyzer is about 0.1 octave. Sounds cool, but why is a wave analyzer such an important component of a flutter meter? By knowing the rotational frequency of moving parts in the tape transport, it is easy to tune to that frequency and determine which parts are the causes of flutter.

While the Micom line of flutter meters were elegant machines, the pro audio devices had no way to measure scrape flutter, an under-appreciated problem during the early years. Eventually, other companies such as Altair, and later Audio Precision, stepped in and incorporated a scrape flutter function into their analysis devices.

The wow and flutter meter environment was populated in the usual fashion. At the lower end of the spectrum were devices designed for hi-fi service shops who worked on consumer-grade cassette and reel recorders. The Leader LFM 3610 and Kenwood FL 180A were popular models. Mid-range devices included the Phillips 6307 and Panasonic VP-7750A.

Long forgotten is the Fidelipak 65-390 which was targeted to broadcasters, and could be used to measure the wow, flutter and drift characteristics of cartridge or reel-to-reel tape recorders, turntables, or film chains. In 1977, it sold for around $350.00. The Sound Technology ST 1510 was also popular with broadcasters, although it was a bit more expensive.

At the top of the pyramid were meters manufactured by Micom. Most were priced beyond the budget of recording studios and radio stations, particularly those with the wave analyzer option.

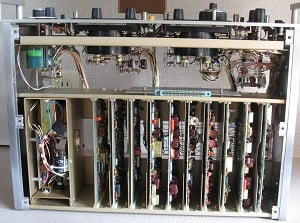

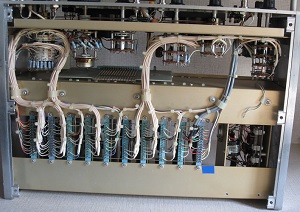

A peek inside the TU-40 reveals why Micom is the Cadillac of the flutter meter industry. All hardware and components are mil-spec. Flawless is the best word to describe metalwork and finish. Circuit boards and wiring harnesses are neat and tidy. All internal tweakers are labeled.

Two sets of standards were in play. For sound recording, the 8100 could measure flutter to either NAB or DIN standards. The 8300 could test telemetry machines to the standards set by IRIG (Intermediate Range Instrumentation Group). The test frequencies are 3.125, 6.25, 12.5, 25, 50, 100, and 200 Khz. The 8300 also had an external audio input, so other frequencies could be used, and some tests could be done with audio recorders - it just wasn't as convenient.

The predecessor to Micom Inc. was Bahrs Industries in Mountain View, CA, a company started by Stanford professor turned audio enthusiast George Bahrs. The company made cutting edge flutter meters, and possibly the FM calibrators used for aligning IRIG instrumentation recorders. Bahrs passed away at age 34, and the company then became Micom, and was moved to Palo Alto. At some later time, they were known as Data Measurements.

Micom (and later Data Measurements) made at least three flutter meters: the 8100 and 8100W (wave analyzer included), for audio recorders; 8200, a wideband device, but not as many frequencies as the 8300; 8300, wideband for testing IRIG instrumentation machines. There may also have been wave analyzer versions of the 8200 and 8300.

also have been wave analyzer versions of the 8200 and 8300.

Still later, 3M acquired the Micom line, renaming it Mincom. After several years, when 3M got out of the tape recorder business, the instruments group was sold off and became Data Check Corporation in San Diego. Data Check continued to manufacture flutter meters and FM calibrators.

The Ampex TU-40 was manufactured by Micom, and is really a private-labeled Micom 8300A.

Our TU-40 came from a college surplus grab in the 1980s. The property tags indicate it belonged to a government agency, and was last calibrated in June of 1980.

When it was acquired, the meter was blowing the fuse on one side of the bipolar 24-volt supply. Replacing the power supply caps made no difference. The problem was traced to a shorted electrolytic on one of the circuit boards. The long and tedious process of replacing all the small electrolytics on all the boards is underway. About half way through, the meter is working, although the audio output waveform looks slightly funky. Since there are many reel and cassette decks in the attic and throughout the residence, the plan is to get it back in working condition, and see if and how well this IRIG machine can work for sound recorders.

Telos Alliance has led the audio industry’s innovation in Broadcast Audio, Digital Mixing & Mastering, Audio Processors & Compression, Broadcast Mixing Consoles, Audio Interfaces, AoIP & VoIP for over three decades. The Telos Alliance family of products include Telos® Systems, Omnia® Audio, Axia® Audio, Linear Acoustic®, 25-Seven® Systems, Minnetonka™ Audio and Jünger Audio. Covering all ranges of Audio Applications for Radio & Television from Telos Infinity IP Intercom Systems, Jünger Audio AIXpressor Audio Processor, Omnia 11 Radio Processors, Axia Networked Quasar Broadcast Mixing Consoles and Linear Acoustic AMS Audio Quality Loudness Monitoring and 25-Seven TVC-15 Watermark Analyzer & Monitor. Telos Alliance offers audio solutions for any and every Radio, Television, Live Events, Podcast & Live Streaming Studio With Telos Alliance “Broadcast Without Limits.”

Recent Posts

Subscribe

If you love broadcast audio, you'll love Telos Alliance's newsletter. Get it delivered to your inbox by subscribing below!